Our Construction Standards

Our best practices approach to our business makes Quality our driving force. We continually search for the best possible tradesmen, products, means and methods available to consistently produce world class projects.

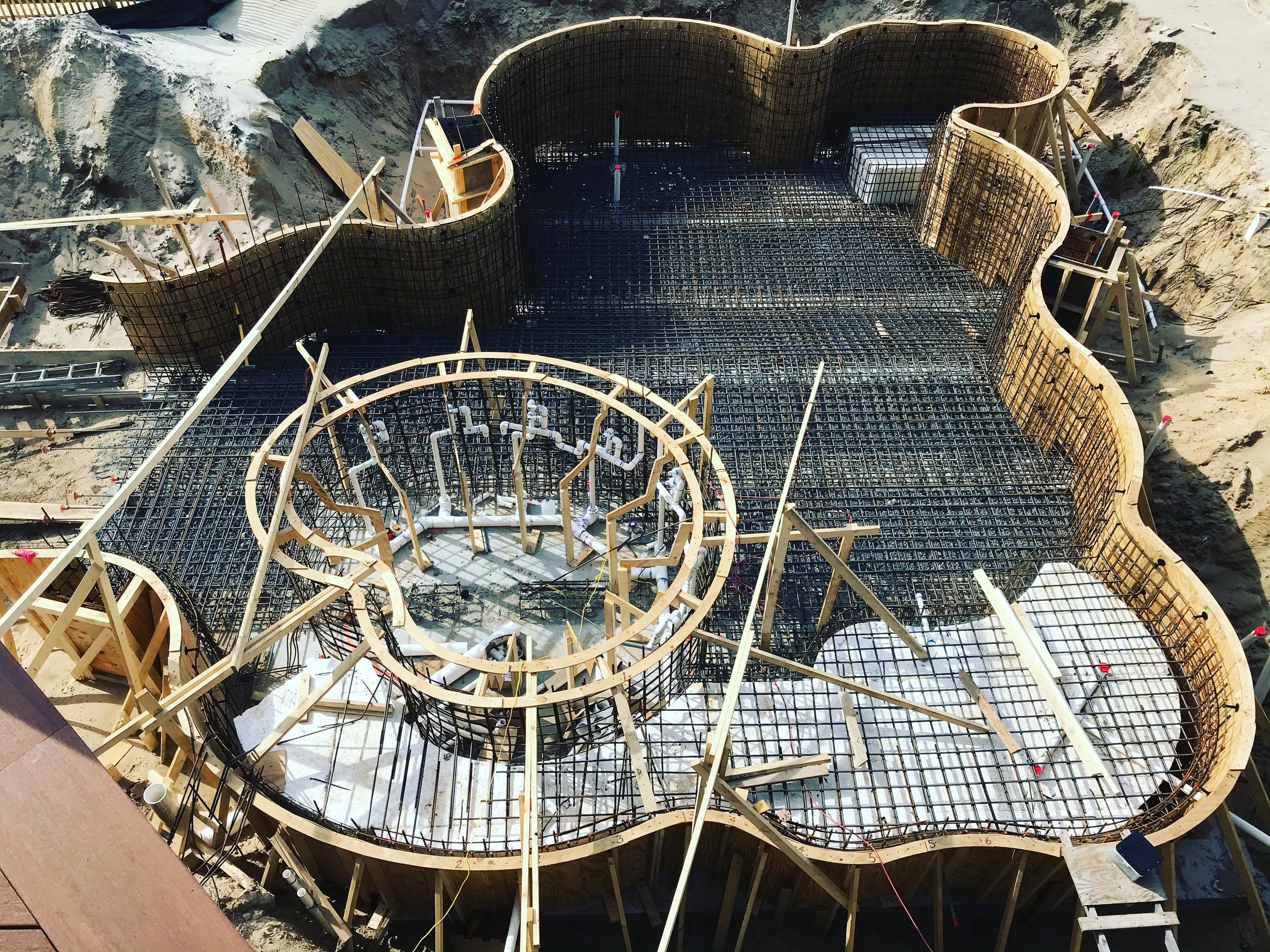

We start each project with the interior or invisible elements of the construction processes. The following is the summation of items we feel set the bar for the highest integral qualitative standards on all our projects.

1. Steel Reinforcement Standards - we follow ACI specifications on rebar sizing, spacing, lap splicing and clearances. This includes every element and any other features of the project that will be concreted, including stairs, benches, water features, etc. to insure long-term stability.

2. Concrete Works - we utilize both Dry and Wet Shotcrete and Cast in Place methodologies in our concrete construction. Each unique project presents its own challenges, and we determine which process is the best match to maintain the highest concrete standards available.

3. Waterproofing - after trying every product on the market, we have selected a product that is consistently chosen by industry-leading engineers and architects. Aquron CPSP is an applied product designed to disallow water penetration and thereby virtually eliminate the production of unsightly efflorescence.

4. Mortars and Grouts - we are currently using Laticrete products for submersed applications. These products set the standards in long-term water exposure for stone, tile, and glass installations world-wide.

5. Plaster - Wet Edge Technologies and Wet Edge Certified installers guarantee that each product is completed on schedule and with the highest quality materials and applicator craftsmanship in the market. Wet Edge products possess superior color and finish longevity.